The battery industry has gone through rapid changes in the past twenty years. We support product developments in the areas of:

— Separators (Lithium, Lead-Acid, Alkaline, Ceramic Coating)

— Food Packaging

— Membranes and Filters

Available R&D Equipment

— Resin dry mixers (1 to 500 kg capacity)

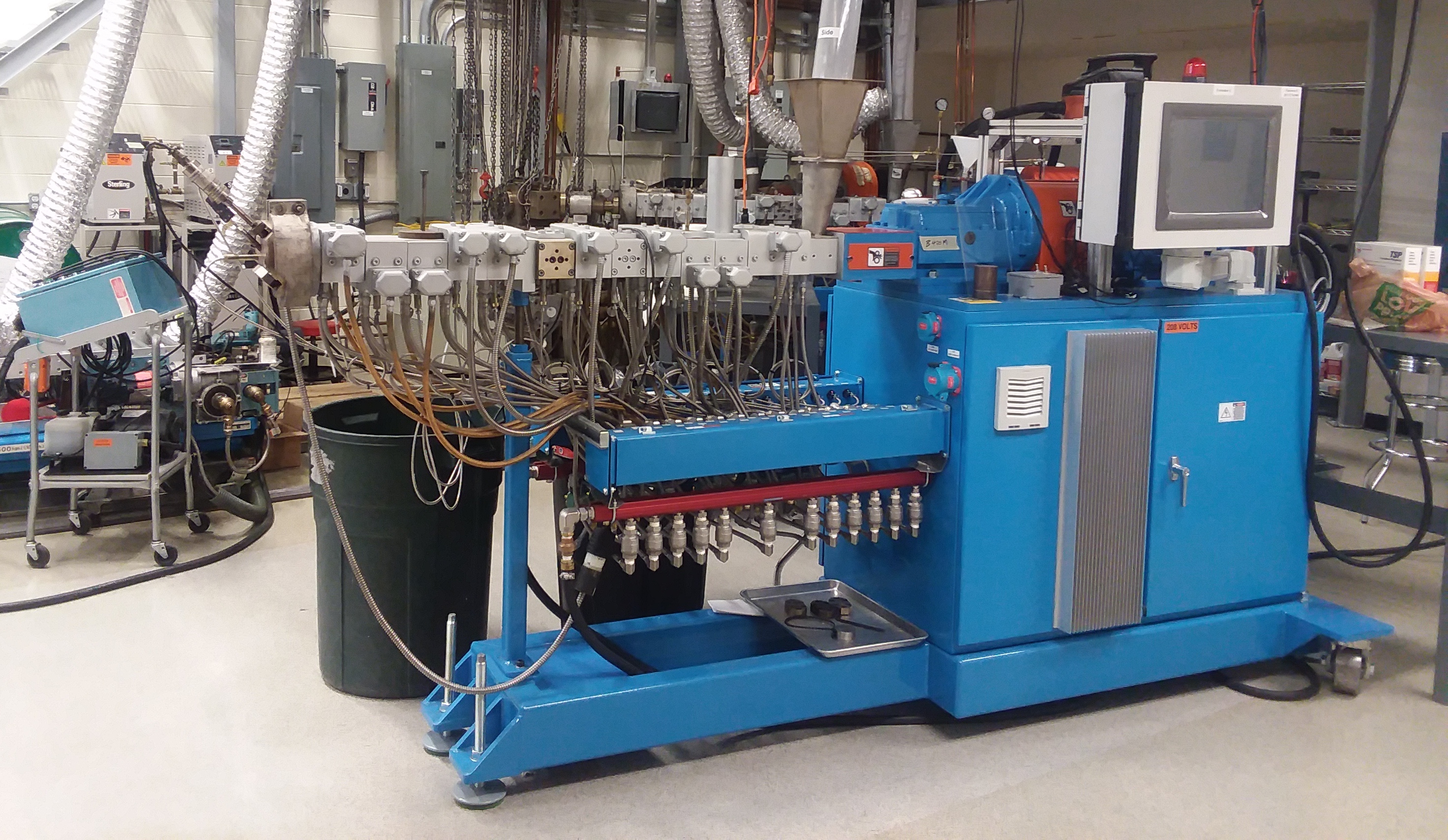

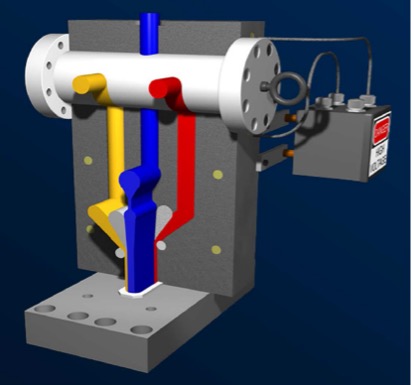

— Twin screw extruder for compounding (high shear liquid injection and vacuum capability)

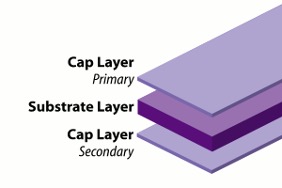

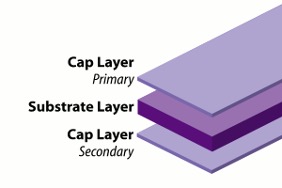

— Thin Film Co-Extrusion (two twin screw 30mm extruders, 10 – 500 microns thickness)

— Cast film die width to 25 cm (multi-layers AA, AB, ABA or ABC configuration layers)

— Cast film lamination capability (to nonwovens)

— Resin moisture dryer prior to compounding (10 to 700 kg capacity)

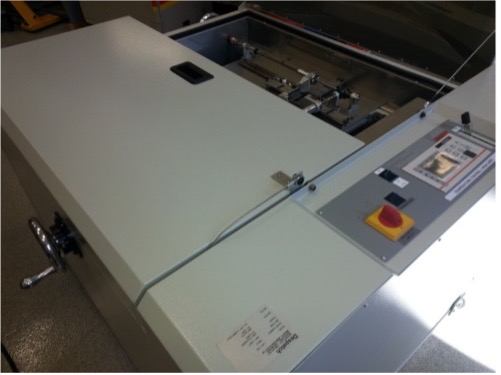

— Longitudinal MDO stretch (1 to 20 m/min)

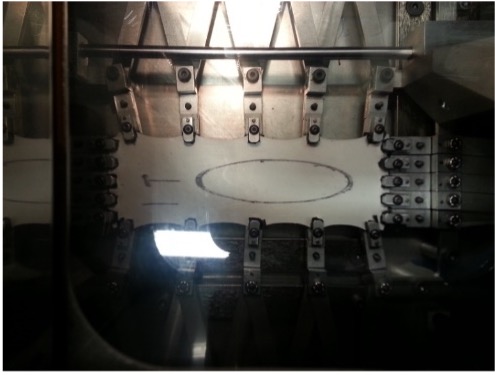

— Transverse TDO stretch (1 to 10 m/min, 10 cm min’ inlet, 100 cm max’ output)

— Laboratory biaxial stretches (4 x 4 cm)

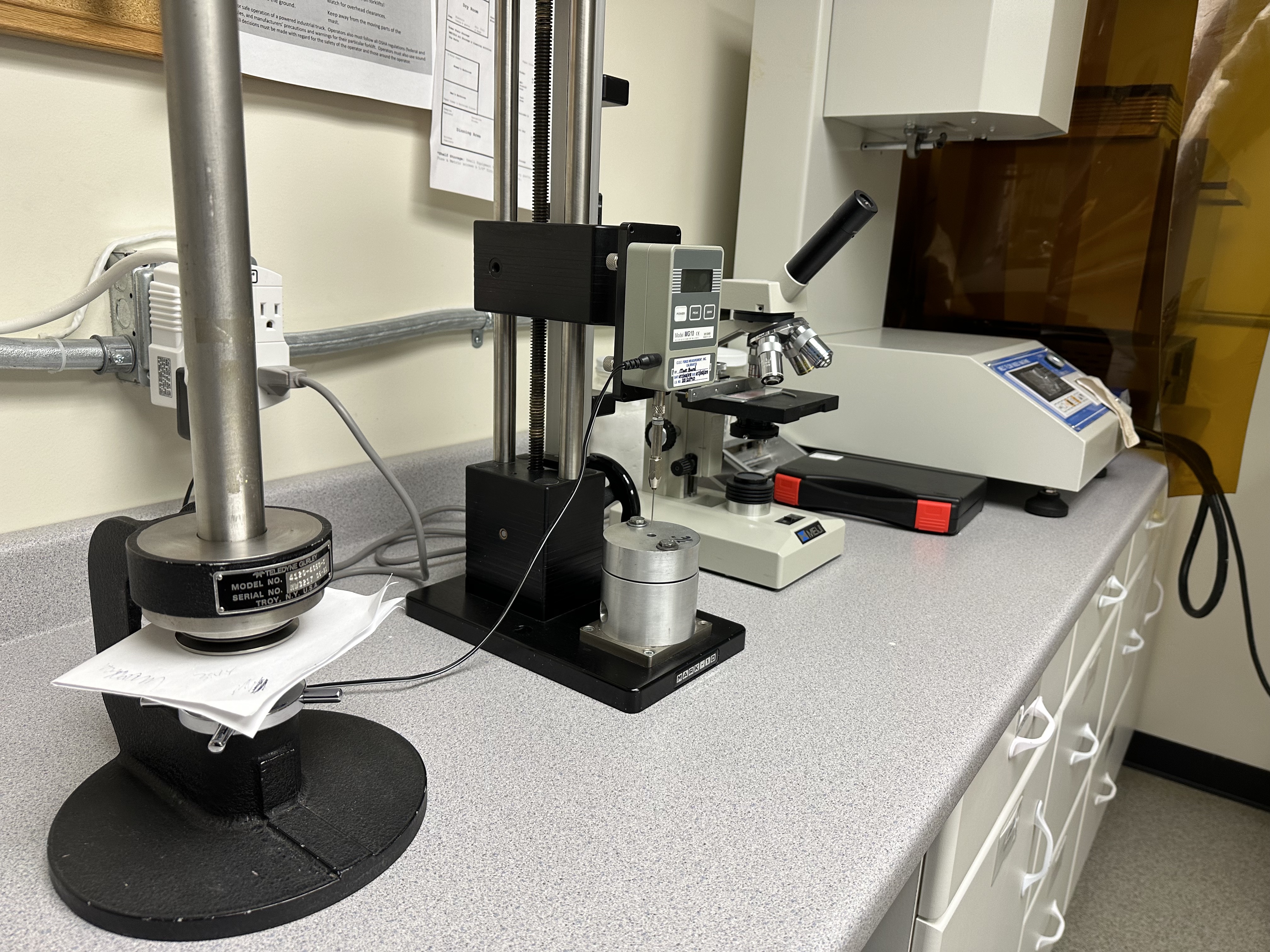

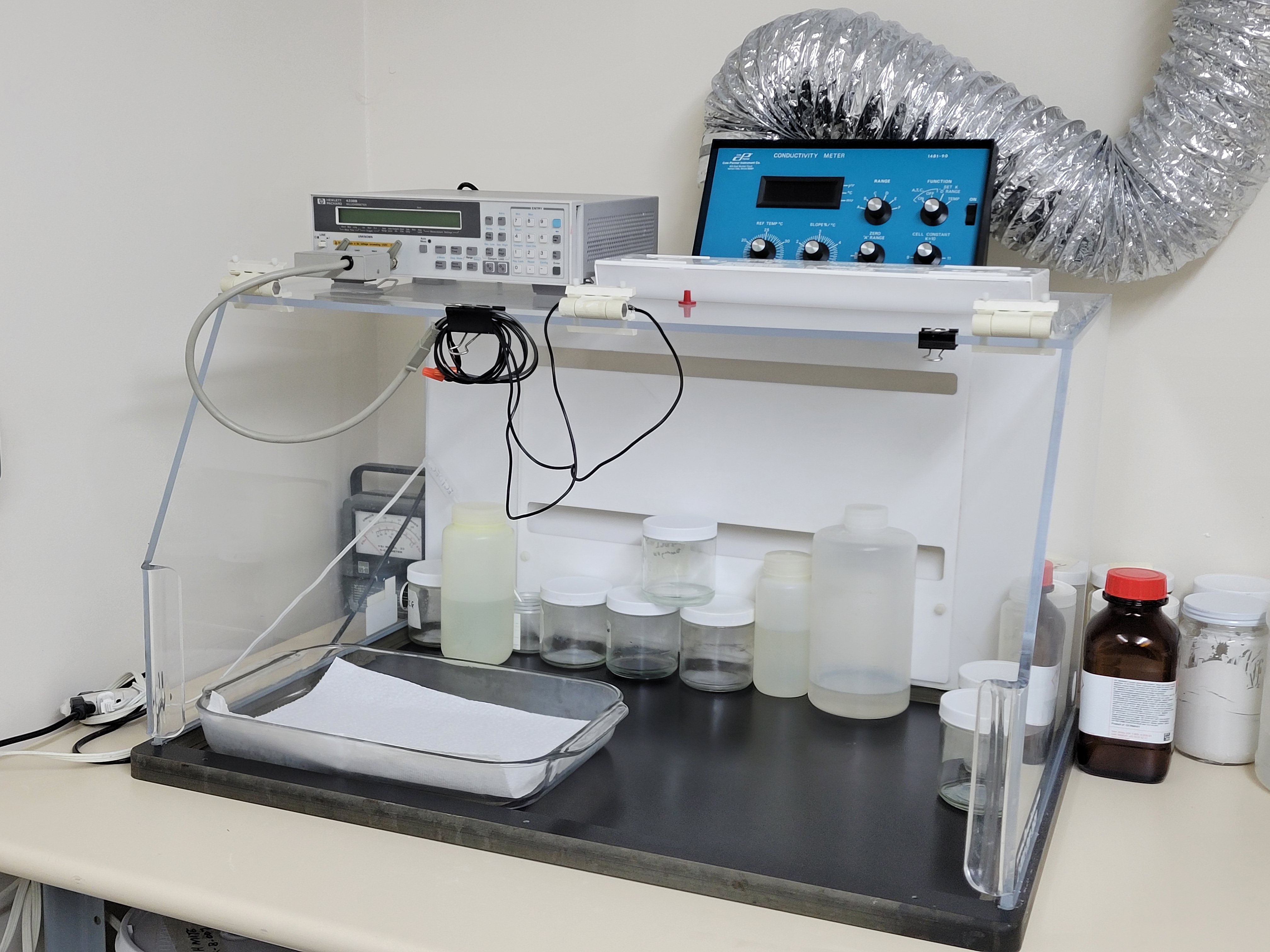

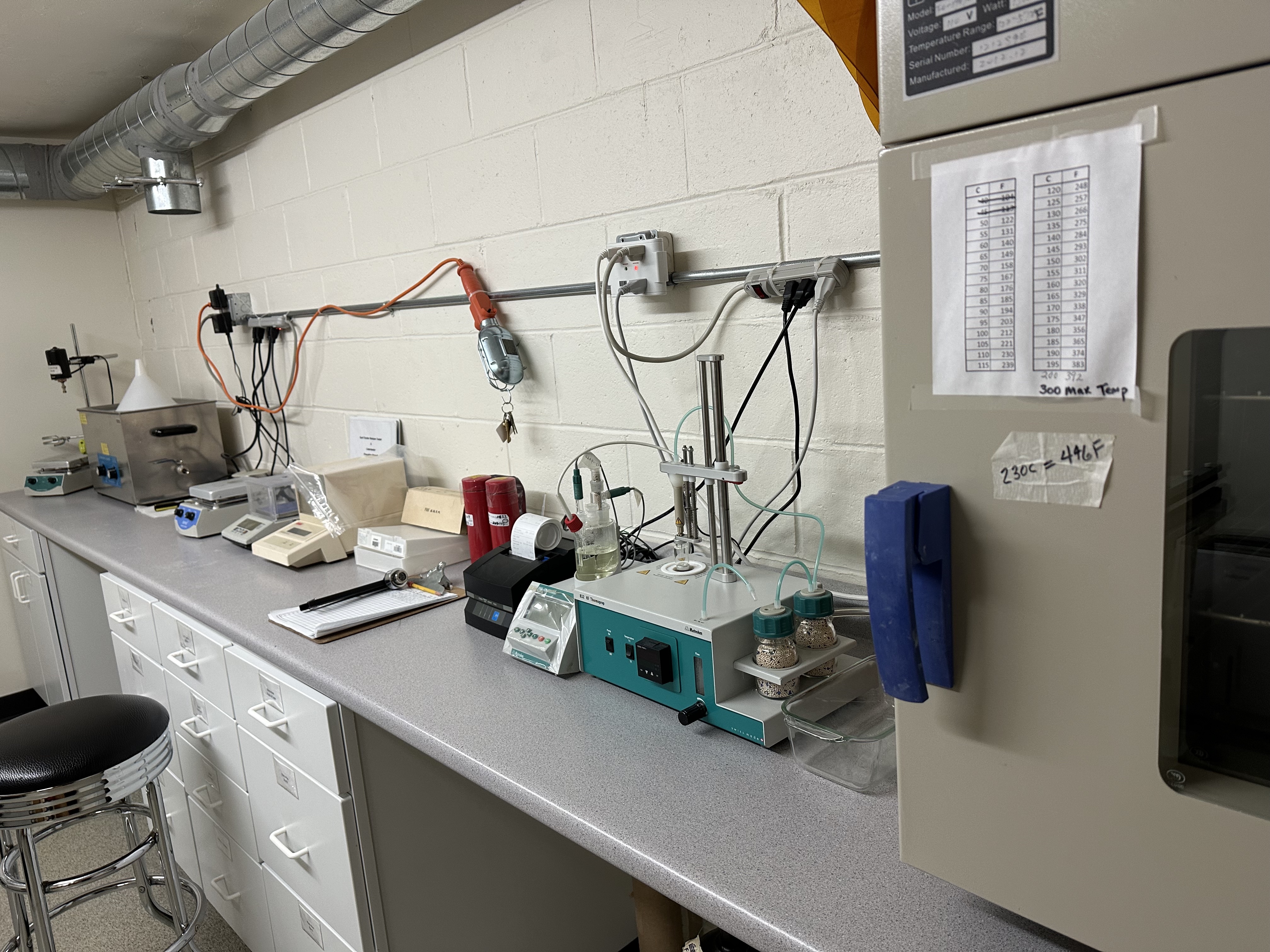

— Lab testing capability (moisture, tensile, puncture, Gurley, porosity, resistance, chemical stability, plus external resources)